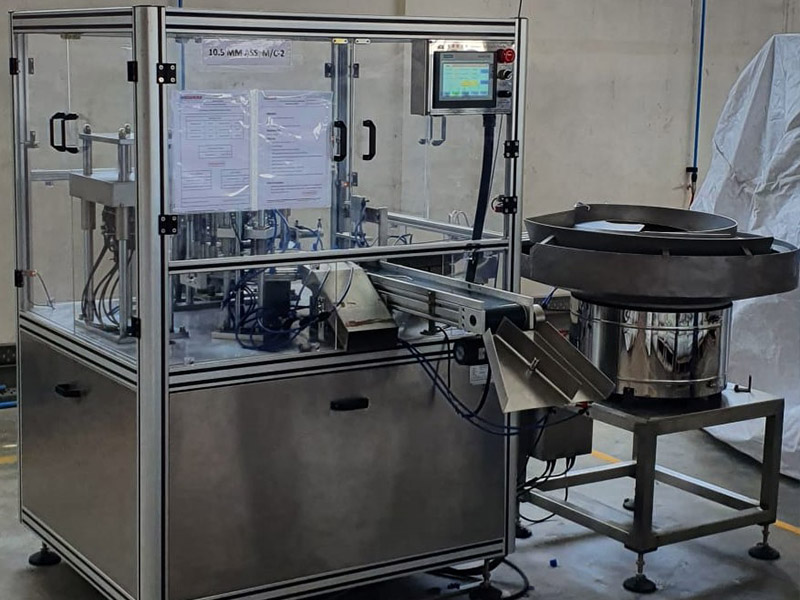

Fully equipped in-house facility coupled with a skilled workforce for automatic, semi-automatic or manual assembly of components with perfection.

As a prominent Plastic Injection Moulding manufacturer, we aim to provide total solutions to our esteemed clients in the same premises. Many of the major industries rely on Plastic Injection Moulding Components for their finished products. Sometimes these parts are manufactured as assemblies of two or more smaller components. Therefore, assembling these parts can be a painstaking task for the manufacturers and need a dedicated team and setup. At the same time, it's crucial that the right components are fitted together properly for best performance. Plus, employing a new team especially for assembling the plastic parts may become challenging and expensive.

Therefore, keeping in mind these challenges, we have developed a dedicated in-house setup that encloses appropriate machinery and tools for assembling finished plastic components into fully functional parts. We deliver superiorly finished parts within the assigned period with the collaborative efforts of our skilled workforce and the fine machinery. All the finished components then undergo diligent testing for factors like leakages, hinge endurance, tamper evident testing etc. to make sure they are able to deliver expected results and have a longer service period. All these activities are carried out meticulously to ensure that the products leaving the facility are best of the quality and exceeding the client’s expectations.